Printable Page

Printable Page

Email This Page

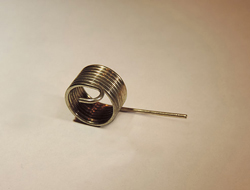

Email This PageTorsion / Double Torsion Springs

Torsion - Double Torsion Spring Manufacturing

Manufacturing of Torsion-Double Torsion Springs

Torsion-Double Torsion Springs

Industrial Torsion-Double Torsion Spring Manufacturing

Custom Torsion-Double Torsion Spring Manufacturing

Precision Torsion-Double Torsion Spring Manufacturing

A Torsion Spring or Double Torsion Spring is a helical spring used to apply torque in a twisting fashion. This type of spring exerts force in a circular arc as its arms rotate around a central axis.

- Manufactured to tight tolerances and stringent quality control standards.

- Specializing in fine diameter, non-standard cross section, and specialty material wire.

Torsion / Double Torsion Springs Capabilities

Specifications

- Wire Sizes

- .005" to .125" Wire Diameter

- Outside Diameters

- .020" to 2.000" Outside Diameter of Spring

Materials

- Special Wire Cross Sections

-

- Round

- Barrel shaped

- Rectangular

- Square

- Special Wire Materials

- R.C. Coil Spring maintains a large inventory of raw materials in an assortment of sizes. If we do not have it, it can be ordered and delivered to us overnight or within a two day period. Stock materials include:

- 302/304 Stainless Steel

- Music Wire

- 17-7 Stainless Steel

- 316 Stainless Steel

- Tin Music Wire

- Zinc Music Wire

- Galvanized Music Wire

- Phosphor Bronze

- Beryllium Copper

- Brass

- Hard Drawn MB

- Galvanized Hard Drawn

- Oil Tempered 1074

- Chrome Silicon

- Oil Tempered Chrome Silicon

- Copper

Capabilities

- Finishing

- R.C. Coil Spring maintains great relationships with quality vendors who will perform all your finishing needs.

- Black Oxide Finish

- Zinc/Tin Plating

- Gold Plating

- Silver Plating

- Powder Coating

- Shot Peening

- Passivating

- Heat Treating

- Electro Polishing

- Tumbling/Deburring

- Rust Preventative

- Additional Services

- To insure that the final product is up to our standards, R.C. Coil Spring provides additional in-house services for its customers.

- Bar Coding

- CAD Design Capabilities

- Color Coating

- Spring End Grinding

- Stress Relieving

- Material and Part Certification

- Packaging on Tacky Boards/Plastic Bags

- PPAPs/First Articles Provided

- Kanban

- Statistical Process Controls